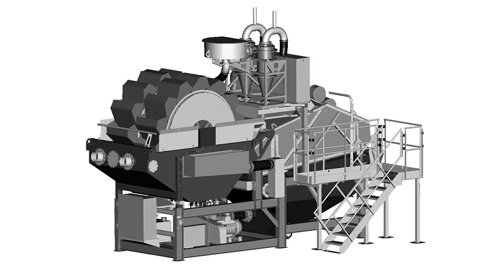

Key Features

• Static sand recovery unit on one chassis

• Twin bucket wheel

• Centrifugal pump

• Twin hyrdocyclones

• Collection tank

• 12 x 5 dewatering screen

• Produce one or two grades of sand

• Designed to work in conjunction with Terex Washing Systems range

Options

• Double grade product

• Bolt on boiler box

• Control panel

• Mobile chassis with single braking axle and suspension

• Dewatering screen spraybars

• Lighting board on mobile chassis

• Adjustable blending chute

Features & Benefits

• Underflow rubber lined slurry pump

• Double bucket wheel with variable speed control

• Two rubber lined hydrocyclone which classifies at approximately 75μm (200 mesh)

• Self regulating cyclone tank complete with built in float system and anti-turbulence sections

• High frequency 12x5 dewatering screen fitted with polyurethane modular mats

• Weir discharge system which reduces the volume of fines entering the cyclone collection tank

• Collapsible bucket wheel tank for easy transport. (Mobile version)

• Bucket wheel performs 80-90% of the work. This keeps the pump and cyclone size to a minimum

• Reduced pump and cyclone wear

• Reduced overall power requirements

• Reduced running costs

• Maximum recovery of material above 75μm (200 mesh)

• Removes silt, slimes and clays below 75μm (200 mesh)

• Removes water following dewatering operation to 10–15% of residual water content

• Major reduction in saleable material discharging to the pond, thus reducing pond maintenance and saving money

• Heavy-duty robust construction ideal for rugged operating environment

• Low maintenance

• All wear areas rubber lined

• Quick assembly time

• Approx 80-120 tph